We know that large projects require greater coordination of materials and service. Budgets and timelines can be tight, and there are always different requirements and regulations to overcome. Even more, it’s vital to have a proper irrigation design, especially when it comes to high-end or municipal projects. A failed design can cost thousands in extra materials or call backs to correct an issue.

Each job, has its own particular layouts, features, water sources and dimensions—so a cookie-cutter solution won’t work. It’s a very detailed oriented and thorough process that varies from one client to the next. Finally, with sustainability and water efficiency on top of mind of customers, efficiency is key—this means it’s a must to work with a Certified Irrigation Designer.

As a business owner, you may not always have the resources to hire an irrigation designer to create a certified design. An irrigation design can make or break winning a project. We understand this can be a challenge. That’s why we offer design services. We want to help you secure jobs of all sizes, even if they require certified water-efficient irrigation designs.

So, what are some of the basics you need to know about irrigation design? We’ve connected with Shane Kreis, Central’s Irrigation Specification Manager, to share his insight and provide you with recommendations for your next irrigation design project, big or small.

From Shane:

The first step to any irrigation design is knowing what you want to accomplish and what your end result is going to be. Getting to the end result is not difficult, but here are a few simple tips that can help get through the overall design process:

1. Identify the Water Source

What is going to supply the water to the irrigation system? You need to know where your water is originating from, whether it be a backflow off of a city water main or a pump out of a pond or well. This is important because the hydraulics will dictate the outcome of the design.

The two key factors about the water source is identifying the flow rate and pressure. Flow rate is how many gallons of water per minute you have available. Pressure is how fast the water moves based on the overall volume of water and the size of the pipe the water is flowing through. You cannot just have one or the other, you need both. Water is what is what your moving and the pressure is how it gets there.

2. Areas of Coverage

On any property, from a small residence to a large commercial property you should be able to identify what is going to be irrigated. Is it flower beds? Shrubs and trees? Turf? It’s vital for the irrigation designer to know as much as possible about what is being irrigated so he knows how much water needs to be used to sustain the area. Another thing to keep in mind is soil texture.

Is it clay? Loam? Silt or sand? Soil texture plays a big role in how much water an area needs when it’s irrigated. The more information a designer has about the area coverage, the more effective and efficient the design will be.

3. Sprinkler Placement

Nothing is ever as simple as it seems, that includes sprinkler placement. When placing heads on a drawing and connecting them with pipe, it’s not dot-to-dot drawing. There is more logic that goes into it that is based on proper hydraulics. Irrigation sprinklers need to be spaced based on a design concept called head-to-head coverage. This means they have a spray radius to spray radius placement.

This concept allows for a uniform distribution of water which produces a consistent precipitation rate—so that all areas are evenly irrigated. Each sprinkler head can be adjusted with a variety of nozzles that will give spray heads flexibility to cover areas that have multiple shapes and sizes and will keep the water distribution consistent.

4. Proper Zoning

Zoning is a critical aspect of the design. It would be simple to water everything the same to save time and money, but plants and turf have different watering requirements and need to be separated. The two most common separations are turf and plant material. Turf itself needs 1” of precipitation each week to remain healthy. Plant material varies depending on the species of plant and some are much more resilient than others. Watering them together will lead to dry spots in some areas and wet spots in others. Proper zoning will keep turf and plant material healthy.

5. Pipe Routing

Mainline and lateral pipe routing complete the zoning separation. The mainline is the artery of the irrigation system which brings water from the water source to all of the irrigation zones. The lateral pipes feed each sprinkler through a zone valve. If everything is piped properly with the correct hydraulics the system will operate at planned. If not, it can have a negative impact on the pressure variations, especially if there are elevation changes in the zone.

6. Types of Product

There are multiple manufacturers in the irrigation industry and each one of them have a similar but unique product. Finding the correct product for the application is not hard, but a matter of preference, price, and what works for your project. From simple spray heads to valve in head rotors, or basic six-zone controllers to 200 station web-based controllers—we have you covered.

If you need help identifying what products will work best for your project, rely on Central to help. We work with the industry’s best manufactures including Hunter, Rain Bird, Toro, Baseline, Tucor, Watertronics, Munro and many more—to offer multiple solutions to get the best result for your irrigation project.

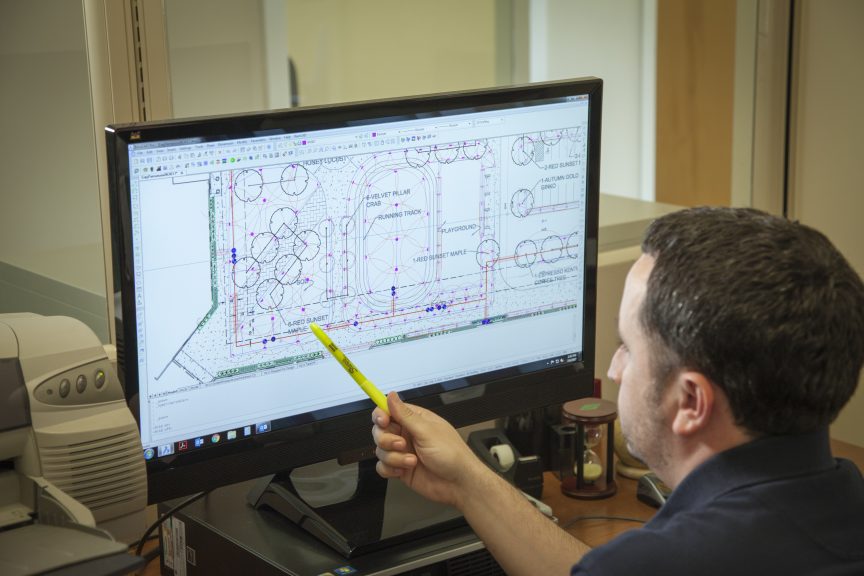

7. Design Interpretation

The most important part of the design is setting it up so someone else can read it clearly. When designs are disseminated down from the original designer they can go through many hands via email, USB-flash drive, or hard copy before it actually gets to the person who is installing the irrigation system. In transition from designer to installer things can be changed which can affect how it is interpreted. So, for that reason the design needs to be clearly labeled and identifiable because once it is out of the designers’ hands anything can happen to it.

Once a project is complete, we highly recommended investing in an as-built drawing. As-built drawings show the actual location of the installed irrigation systems and components versus the original schematic plan. Since the designer has limited involvement with the day-today of the construction, the contractor will be responsible for keeping an accurate list of changes to the original plans. The contractor should keep track of the locations of the controllers, sensors, valves, wire runs, and sprinklers. Once the job is complete and the changes have been identified, the designer can create the final as-built drawing. This will help you be more efficient on your future service calls—think hours, not days.

8. Half Scaling & Plan Copies

One common practice in the construction industry is half scaling and copying. This is when the design is printed in a half scale making it half the normal size it was intended to be. The design is still intact, but the scale of the drawing is reduced in size so it can be printed on a smaller sheet of paper.

The problem with half scaling is the design can then be copied, leaving the drawing open to be misread. When a design is misread, it can lead to a whole host of issues such as wrong measurements and a distorted design. To help combat the issue with half scaling, it’s critical to have a clear and distinguishable legend.

9. Plan Legend

You can have the perfect irrigation design with the perfect intent. You can know where you are when you start and where you want to be when it is done. You can even ask the right questions but if you can’t read the legend properly, the end result can be different from what was intended.

It is crucial for anyone who reads the design to be able to easily read the legend and notes. This will help solve many problems before they begin. Keep the design clear and legible so others can read it. The legend itself should be large and bold with symbols that are clear and distinguishable:

- Pipe size indicators should be clearly marked with the correct sizes and different line weights should be used so when printed or copied the lines can be distinguished from one another.

- Zone valve designation symbols should be listed to identify the zone number, the zone size and the flow rate.

- Sprinkler head type need to be displayed so the size of the head and the nozzles are clear.

- Zone valves should be sized so the correct valve size can be located correctly for each zone.

- Irrigation controller, rain sensors and backflow should all be in their correct location so everything is clear.

Resources to Help Grow Your Business

We understand creating an efficient irrigation system and design is not simple. Trust Central for help, whether it’s questions about drawings, schematic budgetary plans, or sharing knowledge and recommendations on the design tools and software. Central’s design team excels at preparing water-efficient irrigation plans, specifications for projects of all sizes and we stay at the leading edge of the industry. We’re ready to help you grow!

About Shane

Shane Kreis, Central’s Irrigation Specification Manager, has a Bachelors of Science in Applied Geography emphasizing in Resource Management. In addition, Shane has over 20 years of experience as contractor, consultant and distributor from residential, commercial, to golf irrigation systems along with aspects of agriculture. He is a valuable resource for any stage of a project from beginning to end. Shane is a current member of the Irrigation Association and is an EPA Water Sense Partner.